To twobarb, In addition to the 'hands on' test suggested by., I recommend to ask them also a few theoretical questions and see what they answer. Years ago, the Crane Company (does it still exist?) published a booklet titled 'Piping pointers'. Unfortunately, it's not in electronic format. If you let me know your address, I can mail you a xerox copy of it.

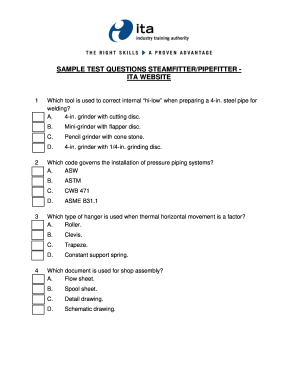

Start studying pipe fitter test. Learn vocabulary, terms, and more with flashcards, games, and other study tools. The authors of this study guide are Bob Harris, Training Director Pipe Fitter Local. It is expected that the UA STAR test candidate is the pipe fitter who has.

To turbolaser, I'm surprised at your answer. You say that if they (the pipefitters) can pass the test you've suggested, most likely they'll be able to weld it. Here in Brazil, pipefitters don't weld and welders don't fit out piping. Looks like in the USA is different.

Crisi Sao Paulo - Brazil. Maybe this is knitpicking. But pipe fitting is not an entry level skill. It really isn't even an advanced level skill. What you are talking about I think is an expert level skill.

To do that kind of work and expect defect free joints and fitups, you will need to provide a skill test.before. you hire. And pay top top dollar to get the skills to come apply. If you are hiring 'liars' thats the problem right there, a resume or somebody elses cert should not be enough to get on the payroll in the first place, and I think that's what your trying to deal with in your original post. There are plenty of textbooks and pipefitters manuals out there. Curv-O-Mark also has materials that might be good for some kind of layout test. Ask the prospective fitter these questions: What is the take out of a 6' 90 degree elbow' answer: 1 +1/2 of the nominal pipe size= 9' How do you figure a 24' offset(center to center) using 45 degree elbows?

Answer: Take the offset(24') x 1.414 =33.9' or 34 inches would be close enough. This would be the center to center length between the two 45 degree fittings. What is the take out for an 8' -45 degree elbow? Answer: 8 4 2 1 you divide the nominal pipe size by 2, four times, then you add the second answer (4) plus the last answer(1) which gives you 5 inches, double that for two 8' 45 fittings and you get 10' How do you figure a rolling offset? Answer: Pythagorus Theorum What is the offset of a 12 inch 90 degree elbow rolled on a 45 degree angle? Answer: any 90 degree fitting rolled on a 45 degree angle is the same take out as the fitting which gives you an answer of.? Since you asked.: Pythagorean Theorem Let's build up squares on the sides of a right triangle.

Pythagoras' Theorem then claims that the sum of (the areas of) two small squares equals (the area of) the big one. In algebraic terms, a2 + b2 = c2 where c is the hypotenuse while a and b are the legs of the triangle. The theorem is of fundamental importance in the Euclidean Geometry where it serves as a basis for the definition of distance between two points. It's so basic and well known that, I believe, anyone who took geometry classes in high school couldn't fail to remember it long after other math notions got thoroughly forgotten. I may be a bit late in the game to respond to this, but happened upon it so. I would have to agree with Lawrence in: the entry level of pipefitting doesn't cover much of the spectrum as fitters go. An entery level fitter should be able to handle simple layouts with standard fittings in the three basic piping categories (butt, socket and thread).

He should also know the standard math and trig functions and the the standard takeups, id/od of the common pipes, or at least where to find them (any of the trusted pocket refs.) If I were to test and 'entry level' fitter I'd probably hand him a basic sketch or iso of a simple pipe system with some 45s 90s and what not and have him give me every thing I need, information wise, to produce that line. If he's competant at that, have him do the layout on some junk or spare pipe. That should give you a rough idea if he's at least entry level. As for resources for tests try NCCER or just google 'Basic Pipefitter's test'. You're bound to dredge up something to help you.

And on the topic of welding/fitting our fitters don't weld unless they've passed the cert for it and usually that's just a 'tack' test. Welders weld fitters fit in our company. Looks like your having the same problem i'm having. I am a shop trained pipe fitter but in the field I have zero experience. In a shop with prints mitters and sadals are nothing to me, but in the field they just say sadal this. I don't have a tool box full of templates and I prefer to layout each one.

One boss I had told me he didn't make a penny unless we fit 500 inches, so we went for a 1000. Now I can get it like that in a shop, but on mt first job in the field I was supposed to tie into a sump pump and my piece came up three inches short because I used measurments another fitter gave me. I didn't last 4 days. I believe on this next opportunity I will ask to be made a 1st class helper no matter how I do on the test so I can retrain and not mess off a good job again.

I have got to ask this question. What kind of pay are you talking about for a prime candidate??? Not that I'm interested, but I am a former 1st class welder/pipe fitter. The job that I had required working with tools such as a contour marker (standard and jumbo), Wrap-a-Round, and several other choice devices that were used to layout pipe and elbows from 6' to 36'. It took me two years to learn the trade from a man who performed as a pipe fitter at the Newport News Shipyard for fifteen years. When I did this work 20 years ago, it was one of the highest payed blue collar jobs in the country.

To get an experienced pipe fitter today, the pay would need to be $25-$30 per hour in the south and even higher in the north east or west coast with GREAT benefits. Whats up people! New to the forum and just want to Thank you guys in advance, for all the help you provide to people that seek more wisdom in their craft. I know this is a welding site and since I have been asked to become more familiar with pipe fitting techniques and concepts. One thing I noticed after rummaging thru the different threads here is that everyone seems to dance around this simple question. 'Does any one have a copy of a basic entry level pipe fitters test?' I'd like to add to this question.

Does any one have or know where to download a free copy of a basic or advanced level pipe fitters test or any kind pipe fitting test online? The question never got answered and after doing a complete and in depth search for days online still to no avail! Its like a top secret thing if you can't pay for it (NCCER) you can't get it! Any help would be greatly appreciated.

I think every company usually has their own kind of test. Best thing to do would be to ask them to figure some things out on paper (offsets, takeoffs, blueprints). Arkansas plumbing test requires you to look at a blueprint and figure out how much tube/pipe, how many and what size of fittings, and so on.

Pipefitter Helper Study Guide

Some jobs I've been on require fitters, in this case tube benders, to bend tube by taking measurements from a jig and then installing the tube into it. A paper test to see how much they know and a hands on test (12 on 12 branch or 8 on 12 branch) to see if they can use what they know and what kind of work they can do.